CNC Punching Services

CNC Turret Punching with Laser Cutting

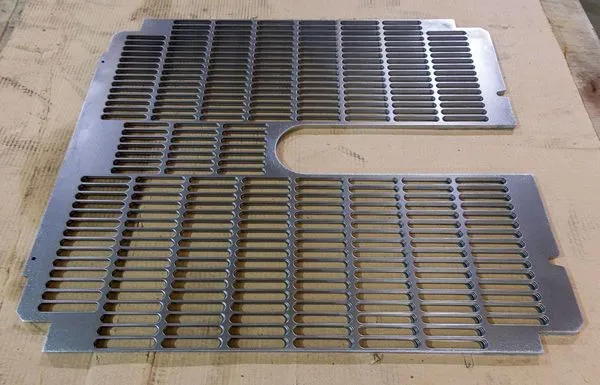

Our Amada Acies 2515T combination CNC Turret Punch with Laser cutting offers reduced processing times and quick turnaround for parts requiring lots of holes, perforating, or tapping. Punching allows us to form louvers, bend short flanges, form progressive ribs, emboss, countersink, and coin holes.

High Precision CNC Turret Punching with Laser Cutting Equipment

Combining Punching and Laser cutting processes in the same machine reduces processing cycle times and part cost. The punching, laser cutting and automation features of the Acies 2515T provides unmatched productivity and scratch-free processing of complex sheet metal parts. The machine is equipped with an automated multi-shelf storage tower with shelves for both raw material and completed parts. The automation provides for off-hours of unmanned operation during times of peak demand.

Additional processes include etching, part marking, perforating, forming, coining, countersinking, embossing, extruding, and tapping of precision sheet metal parts. With hole punching speeds of up to 400 holes per minute, it is much faster to punch holes than to laser cut. The Amada Acies includes a 300-station tool changer - eliminating setup times when changing from one part to the next. This all adds up to faster throughput and less expensive parts.

Turret Punching Capabilities

Material Processing Capabilities

- Material Thicknesses: 22-gauge sheet metal - 1/4" plate

- Max Part Size: 60" x 120"

- Laser Power: 4 Kilowatts

- Max Punch Force: 33 Tons

- Capacity: Capable of Lights-out manufacturing

Max Hole Punching Diameters

- 13-gauge: 4.500" Diameter

- 11-gauge: 3.500" Diameter

- 10-gauge: 3.000" Diameter

- 3/16": 2.250" Diameter

- 1/4": 1.625" Diameter

Additional Punching Features

- Perforating: Guards, Panels, Partitions, Enclosures, Screens, and Sheets

- Forming: Louvers, Etching, Extruding, Embossing, Countersinking, Coining, and Stiffening Ribs

- Tapping: up to 1/4"-20

Why Choose Andersen Industries

Since 1966, Andersen Industries has been using hands-on engineering and innovative engineering solutions to create, design, and build products for our customers that are high-quality and long-lasting. Over the years, our company has become a premiere metal fabricator of precision metal products with unmatched quality. When you work with us, you can expect precision, professionalism, and timeliness throughout each stage of the process. Our modern, well-equipped 108,000 square-foot manufacturing facility in Southern California offers a single source, one-stop-shop solution for our divisions of Precision Metal Fabrication, Machining and Welding and Welding Systems. Our strategic supply network ensures we source the highest-grade metals available, and we offer delivery options on most of our products

Request a Quote for Precision Turret Punching with Laser Cutting Services

Andersen Industries has the equipment, facility capacity, and manufacturing expertise to get your turret punching project done faster. We are passionate about delivering high-quality products and look forward to working with you on your project. Contact us to discuss your precision sheet metal punching needs.

Request a Metal Fabrication Quote