WeldPro 360 High-Vacuum Weld Fume Extraction System

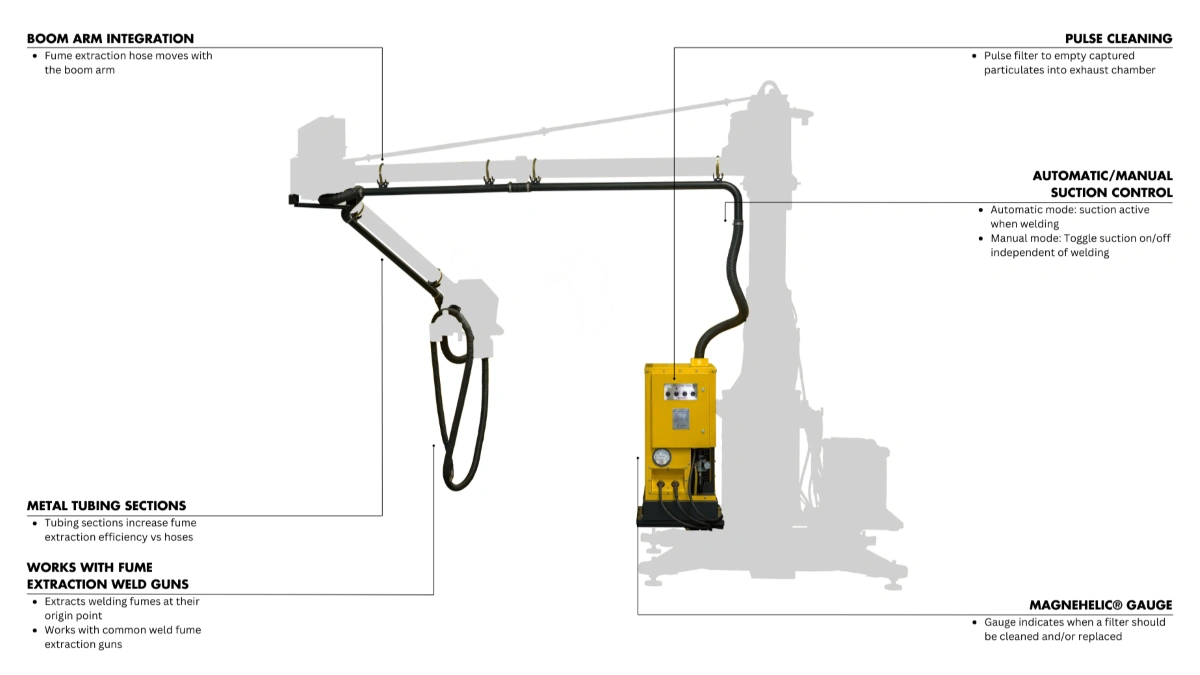

The WeldPro 360 High-Vacuum Welding Fume Extractor connects to weld fume guns to capture hazardous weld fumes at their source. This system integrates with WeldPro 360 LRW MIG welding boom systems to effectively extract weld fumes while welding on large and oversized weldments. This integration delivers cleaner air for operators without requiring them to reposition additional equipment in between welds. Additionally, it can be used as a standalone fume extractor. Automatic Start/Stop Mode engages fume extractor only during welding, for efficient power consumption. Adjustable suction power allows for optimizing fume capture and avoiding shield gas disturbance. Pulse Cleaning enhances MERV 15 filter performance over its life.

Benefits

Capture Weld Fumes Where They Are Produced

- Weld fume guns extract fumes right from the tip of the MIG gun

- No other extraction method is both as effective and flexible

Extract Fumes Even While Welding Large Weldments

- Extract fumes anywhere within the work envelope of our LRW MIG welding boom arms

- Max reach is 28 feet from the boom's main pivot, and up to 23 feet off the ground

Clean Air for Welders Without Slowing Them Down

- Welding with our fume extraction system is as quick as welding without it

- Integrating vacuum tubes into a WeldPro 360 boom arm reduces shop floor clutter

Features

- Integrates with all LRW MIG welding boom arm models

- Compatible with weld fume guns from major manufacturers, including Lincoln, Miller, Abicor Binzel and Tweco

- Pulse Cleaning enhances filter performance and life

- Automatic Start/Stop Mode engages fume extractor only during welding

- Durable Powder Coated Finish

- Steel tubing for increased vacuum efficiency

- UL Listed Electrical Components

Specifications

| Filtration Rating: | MERV 15 |

| Maximum Vacuum: | 83-in. Water Column |

| Maximum Flow: | 145 CFM |

| Motor: | 2.70 HP |

| Length: | 36.7 in. |

| Width: | 18.5 in. |

| Height: | 39.1 in. |

| Weight: | 403 lbs. |

| Voltage: | 208-230V 3PH / 460-480V 3PH (with transformer) |

| Hose Diameter: | 2-in. ID |

*Please note that product specifications are subject to change as we continuously improve our products.

Operating Requirements

Electricity: 208-230 Volts, 3-Phase

Power Cord: 22 ft.

Compressed Air: 90 PSI

Air Hose Connector: 1/4 NPT Industrial Male

Fume Extraction System Accessories

LRW Boom Arm Integration Kit

Connect the High-Vacuum fume extractor to any LRW weld boom arm

Boom Column Mounting Kit

Mount the High-Vacuum Fume Extractor to any WeldPro 360 column

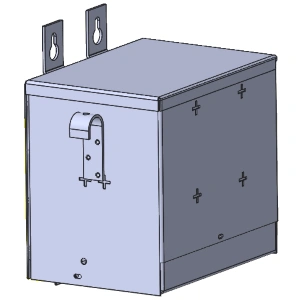

High-Voltage Transformer

Allows for 460-480V 3PH compatibility

4-inch

Caster Kit

Makes the High-Vacuum Fume Extractor mobile

Additional Resources

View Other WeldPro 360 Products

Want to know more about WeldPro 360 High Vacuum Fume Extractors?

Contact us for pricing, product questions, or help configuring the right boom system for your operations. We will respond promptly to provide the information you seek.