CNC Turning Services for Precise Machining Needs

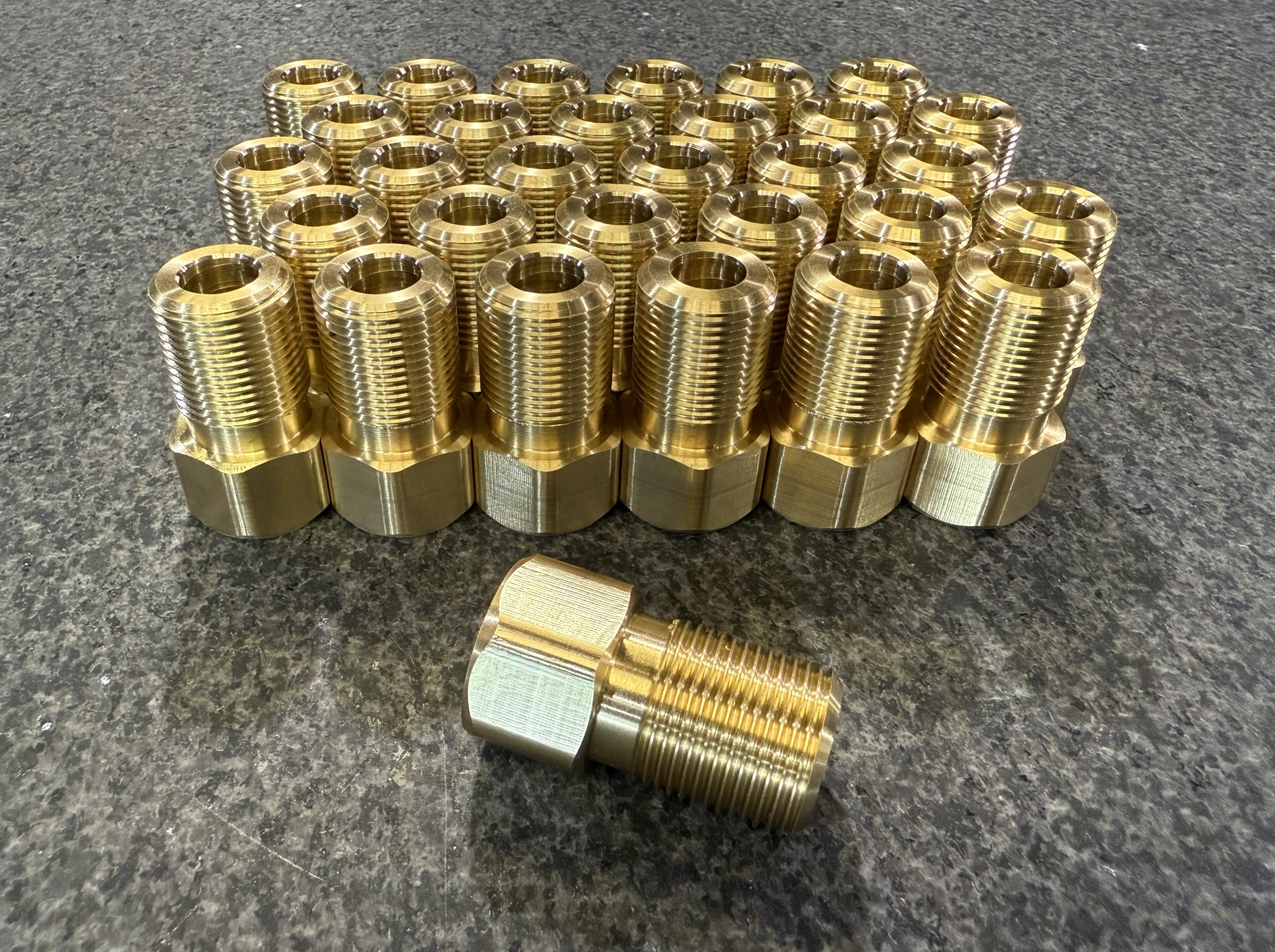

Precision CNC Turning Services

Whether your machining needs are small or large, simple or complex, Andersen Industries has the people, equipment and experience to meet your timeline. We use advanced turning equipment to machine components, weldments, castings, and forgings from Aluminum, Carbon & Alloy Steels, Stainless Steel, Brass, and Cast Iron.

We offer a comprehensive range of precision CNC turning services to fulfill various machining requirements. Our advanced CNC lathes, equipped with both 2-axis and 5-axis capabilities, enable us to deliver high-quality components with tight tolerances.

In-House Fixture Design & Build

Our skilled engineers provide in-house fixture design and build services, ensuring optimal stability and accuracy during the CNC turning process. This meticulous attention to detail guarantees the best possible results for your projects.

From Prototypes to Production

Whether you need prototypes for initial testing or full-scale production runs, our CNC turning services have you covered. Our efficient processes and state-of-the-art machinery allow us to seamlessly transition from prototyping to mass production without compromising on quality.

Diverse Range of Machinable Objects

From weldments and castings to forgings and parts made from various materials, our CNC turning expertise extends to a wide array of components. We handle all types of materials with precision and efficiency.

Order Quantity Flexibility

Andersen Industries understands that production requirements can vary. That's why we offer flexible production quantities to cater to your specific needs. Whether you need a small batch or a larger production run, we're here to deliver.

Cutting-Edge CNC Turning Machines

Our commitment to excellence is reflected in our state-of-the-art CNC turning machines. We operate a range of high-performance machines to ensure top-tier results for your projects.

Mori Seiki NZ1500 T2Y2 Lathe with Gantry Loader

- Max Turning Diameter: 11.8"

- Max Turning Length: 31.9"

- Chuck Size: 6"

- Turrets: 2

- Spindles: 2

- Tool Stations per Turret: 16, with Live Tooling Capability

Mori Seiki NZ1500 T2Y2 Lathe with Bar Feeder

- Max Turning Diameter: 11.8"

- Max Turning Length: 31.9"

- Chuck Size: 6"

- Turrets: 2

- Spindles: 2

- Tool Stations per Turret: 16, with Live Tooling Capability

Haas ST-40 CNC Lathe

- Max Turning Diameter: 25”

- Max Turning Length: 44”

- Chuck Size: 15”

- Spindle Bore: 4.6”

- Tool Stations on Turret: 12

- Programmable Tail Stock

5-Axis Turning — DMG Mori Seiki NTX 2000/1500SZM Integrated Mill-Turn Center

- Max turning diameter (upper, B-axis): 25″

- Max turning diameter (lower turret): 10.7″

- Max turning length: 60″

- Rotation on upper turret (B-axis): ±120°

- Tool stations on upper (B-axis): 76

- Tool stations on lower turret: 10, with live tooling

The NTX features all-around machining for complex geometries, from micro-fine work to large parts. This mill-turn center offers a super-high-pressure interface and high-torque spindles. The high-torque spindles with 8″ quick-change chucks and a workpiece unloader enable high-volume jobs. The DMG Mori Seiki NTX 2000/1500SZM uses Capto tool holders and delivers excellent productivity.

Contact Us for Expert CNC Turning

Andersen Industries is the right choice for all your manufacturing needs. As a full-service shop, we offer everything from CNC machining to CNC metal fabrication, welding, painting, and assembly. You can trust us to get the job done right and in the timeline you need. Contact us to discuss your requirements with our CNC turning experts.

Discuss Your Machining Requirements