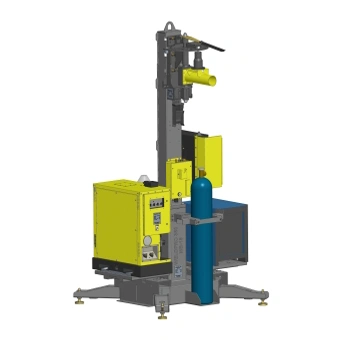

WeldPro 360 LRW-18P MIG Welding Boom Arm

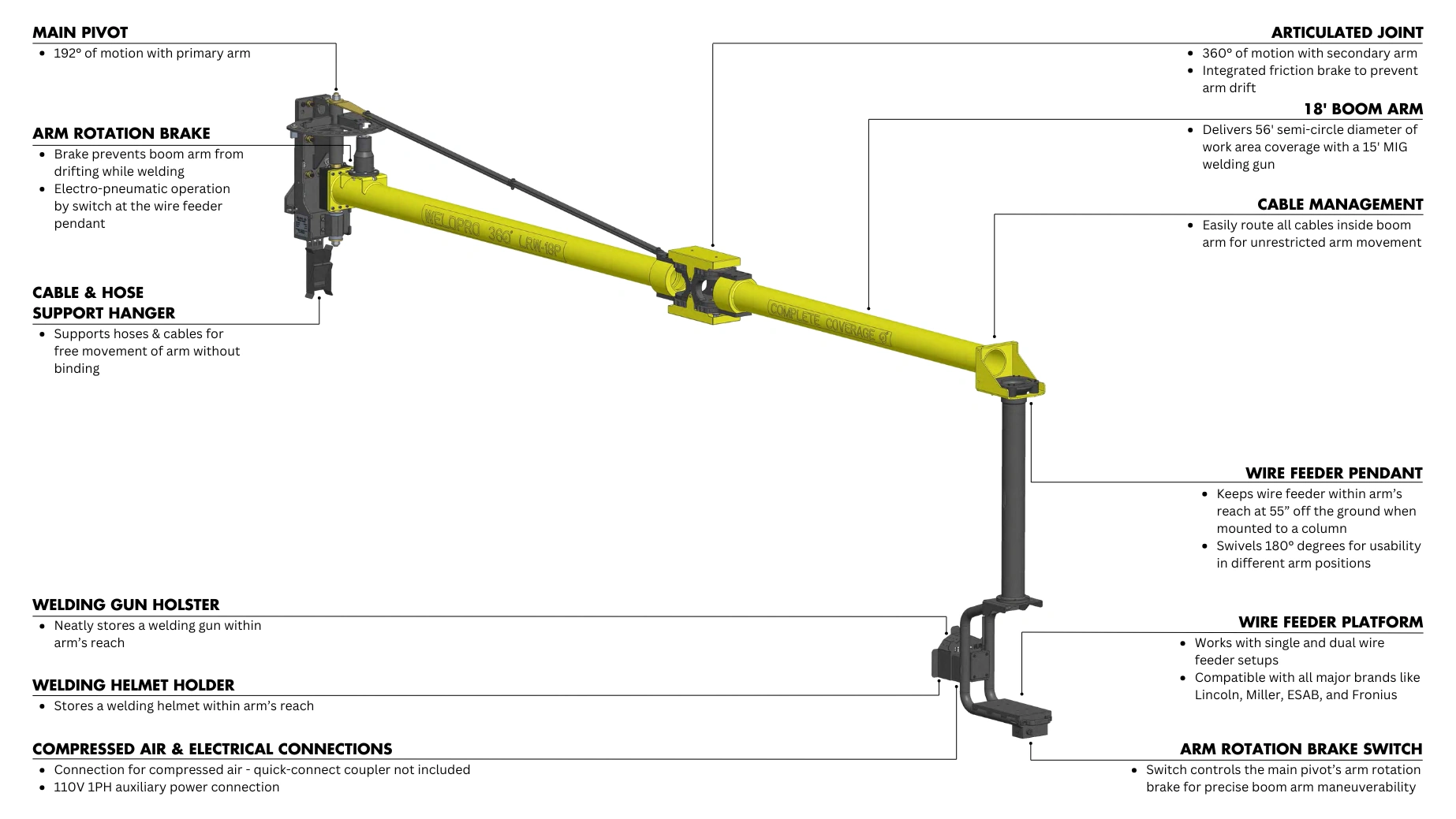

The WeldPro 360 LRW-18P boom arm delivers the same double-articulated performance enhancing capabilities as the revolutionary WP360 LRW-18, but with a simplified design. The WP360 LRW-18P differentiates itself by eliminating the vertical motion of the secondary arm. If you don’t need to weld at extended heights—more than 10’ above the floor—then the WP360 LRW-18P is a great choice.

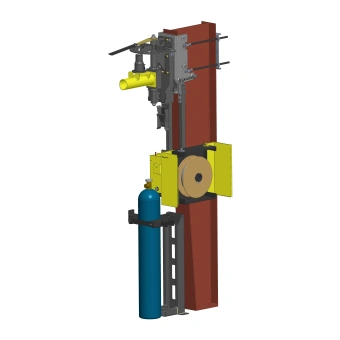

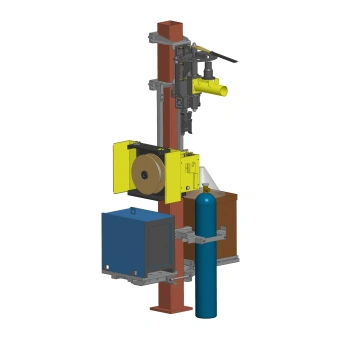

The standard mounting height for the WP360 LRW-18P arm is 10’ and the arm incorporates a unique, swiveling pendant—at the end of the secondary arm—which mounts the wire feeder a comfortable 60” above the floor for easy access to welding controls and boom operation. Don’t be fooled into thinking the pendant hinders the boom operation, in almost every case the double-articulation capabilities of this unique arm, allow you to fold the secondary arm back alongside of the primary arm (effectively shortening the arm to 10’) and quickly maneuver around obstructions.

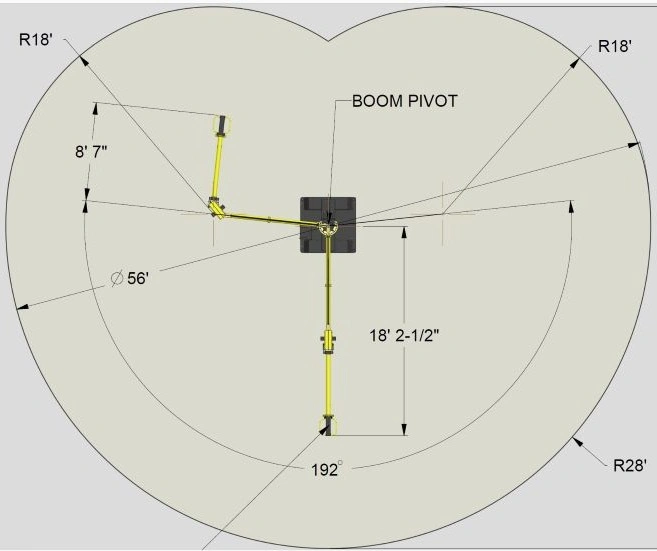

The primary arm is 10’ long and the secondary arm is 8’ long. The primary arm rotates 192° around the main pivot point, providing complete welding coverage within a 56’ diameter semi-circular welding zone when using a 15’ MIG welding gun. The secondary arm rotates a full 360° about the end of the primary arm and eliminates all unreachable dead zones, common to single-articulated, straight-arm booms.

Create clean and organized welding cells by routing all hoses and cables within the interior of the WP360 LRW-18P’s welding arm—no more unsightly cables and hoses hanging from the arm or laying on the shop floor creating a safety hazard. The primary arm incorporates an electrically controlled, positive stop rotation brake and the secondary arm has a no touch friction brake to hold the entire arm in position. Ball bearing pivot points make repositioning the arm an almost effortless task, moving from position to position in mere seconds.

With the ability to mount wire feeders from any supplier of choice, you can place the necessary welding controls right where the operator is working, no more wasted time going back and forth to the welding machine to make adjustments to the weld process.

When installing the WP360 LRW-18P arm, there are five basic options available from which to choose, giving you the ability to tailor your installation for maximum return on investment. The options range from a wide-open, do-it-yourself approach, to a fully engineered and ready to install solution, using readily available, WeldPro 360 designed and engineered components.

Install a WeldPro 360 LRW-18P MIG welding boom arm in your shop and like hundreds of other shops, you will see your productivity soar!

Benefits

- Increased weld productivity

- Complete coverage of the welding area with no dead zones

- Quickly move from weld to weld with minimal effort

- Clean, organized weld cell with no unsightly dangling cables or hoses

- Excels when using heavier wire feeders (over 100 lbs.)

- Lower-cost alternative to the WP360 LRW-18 (non-pendant, elevating secondary arm)

- Improved safety through reduced trip hazards and minimized operator strain

Features

- 18’ long double-articulated boom arm, pendant style

- 192° primary arm rotation with electrically switched, positive-rotation brake

- Secondary arm rotates 360° around the end of the primary arm

- Secondary arm rotation uses a touchless, automatic rotation brake

- 180° pendant rotation for optimal positioning of the wire feeder

- All cables and hoses are routed inside the arm tubes

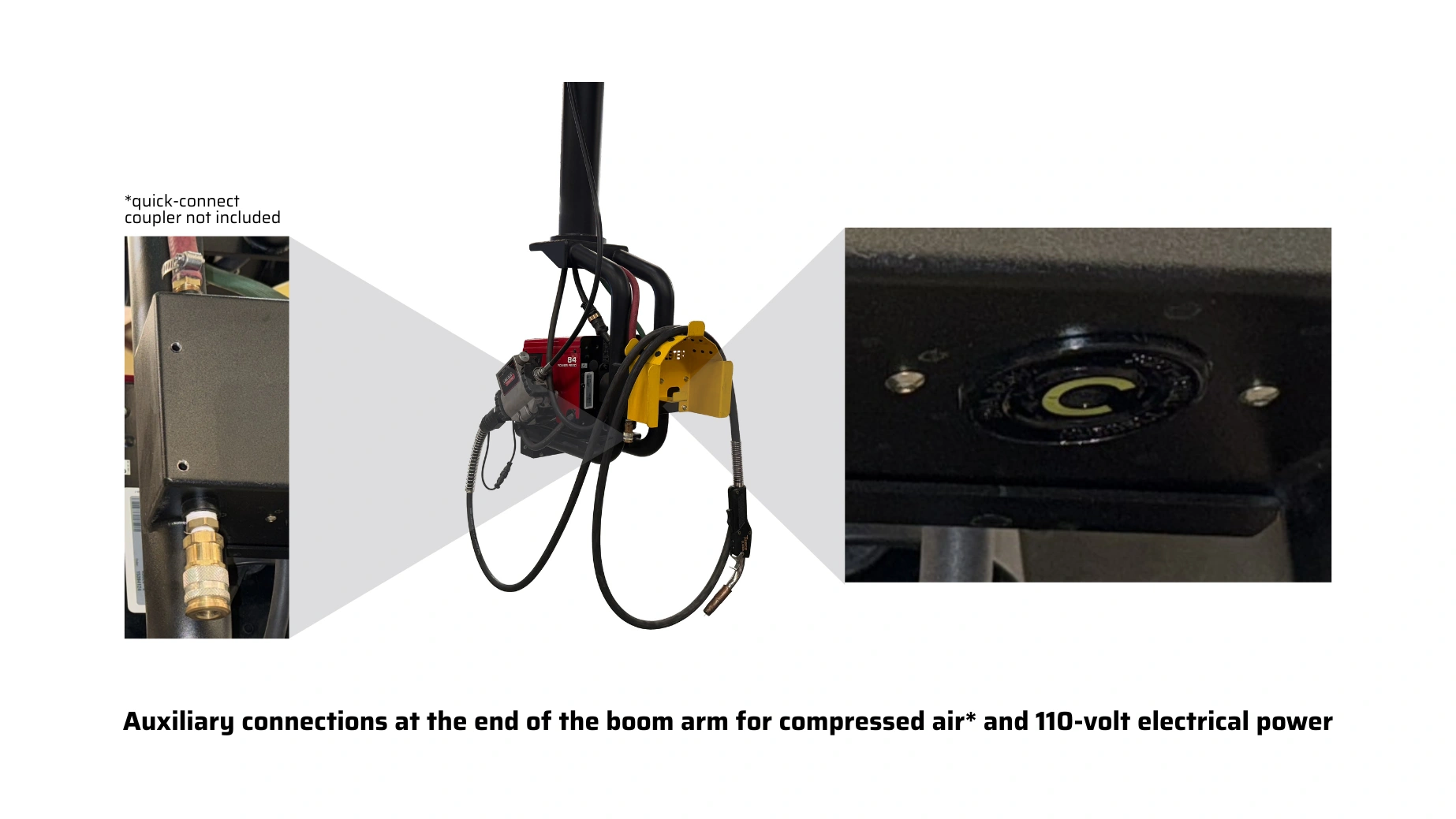

- Auxiliary compressed air connection at the end of the boom arm

- Auxiliary 110-volt electrical power connection at the end of the boom arm

- Built-in weld gun cable holster stores the weld gun when not in use

- Durable, safety-yellow powder-coated finish for high visibility and safe operation

Specifications

| Boom Arm Length: | 18 ft. (10-ft. Primary Arm, 8-ft. Secondary Arm) |

|---|---|

| Recommended Arm Mounting Height: | 10 ft. (8 ft. Option Available) |

| Boom Arm Weight: | 425 lbs. |

| Weight Carrying Capacity (Wire Feeder): | 120 lbs. |

| Power Requirement: | 120 Volt |

| Compressed Air Requirement: | 90 PSI Minimum |

*Please note that product specifications are subject to change as we continuously improve our products.

Boom Mounting Options

Option 1

Customer-Designed Solution

Install your WeldPro 360 boom arm with a solution that you design and build yourself

Option 2

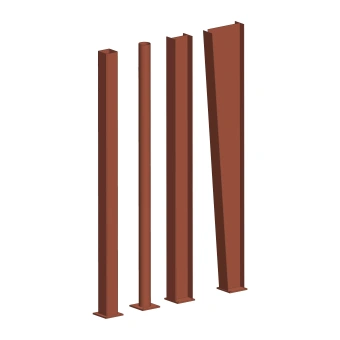

Tapered Column Mounts

Install your WeldPro 360 boom arm to a tapered column using WeldPro 360 purchased mounts

Option 3

Straight Column Mounts

Install your WeldPro 360 boom arm to a straight building column using WeldPro 360 purchased mounts

Option 4

Floor-Mounted Column

Install your WeldPro 360 boom arm to a WeldPro 360 Floor-Mounted Column anywhere in your shop

Option 5

Freestanding Column

Install your WeldPro 360 boom arm to a self-contained WeldPro 360 Freestanding Column with fast setup and built-in portability

Learn More About Mounting Options

Getting the most out of a WeldPro 360 weld boom requires a well thought out installation. Click below to explore the available options.

Explore Mounting OptionsWelding Equipment Accessories

Additional Resources

Other Welding Boom Arms

View Other WeldPro 360 Products

Want to know more about WeldPro 360 LRW-18P MIG welding boom arms?

Contact us for pricing, product questions, or help configuring the right boom system for your operations. We will respond promptly to provide the information you seek.

Request More Info