Welding & Fabrication Services

Dependable Welding Solutions, Built for Performance

When your equipment depends on precision, you need more than just a supplier—you need a fabrication partner you can trust. At Andersen Industries, we deliver high-quality, custom-manufactured welding components on time and to spec. Whether you're sourcing parts for OEM production or tackling unique fabrication challenges, we offer turnkey solutions tailored to your welding needs—with the reliability, innovation, and responsiveness your operation demands.

Contact us today to learn more about our capabilities and how our team can manage the production of your metal parts.

Contact Us

Welding & Fabrication Equipment

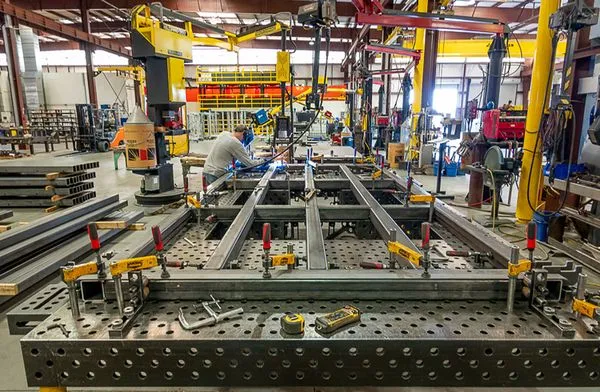

Our MIG and TIG welding equipment includes Advanced Process Welders and system controls mounted on our state-of-the-art WeldPro 360 MIG Welding Booms. Andersen Industries developed the Booms to increase productivity and efficiency on large weldments.

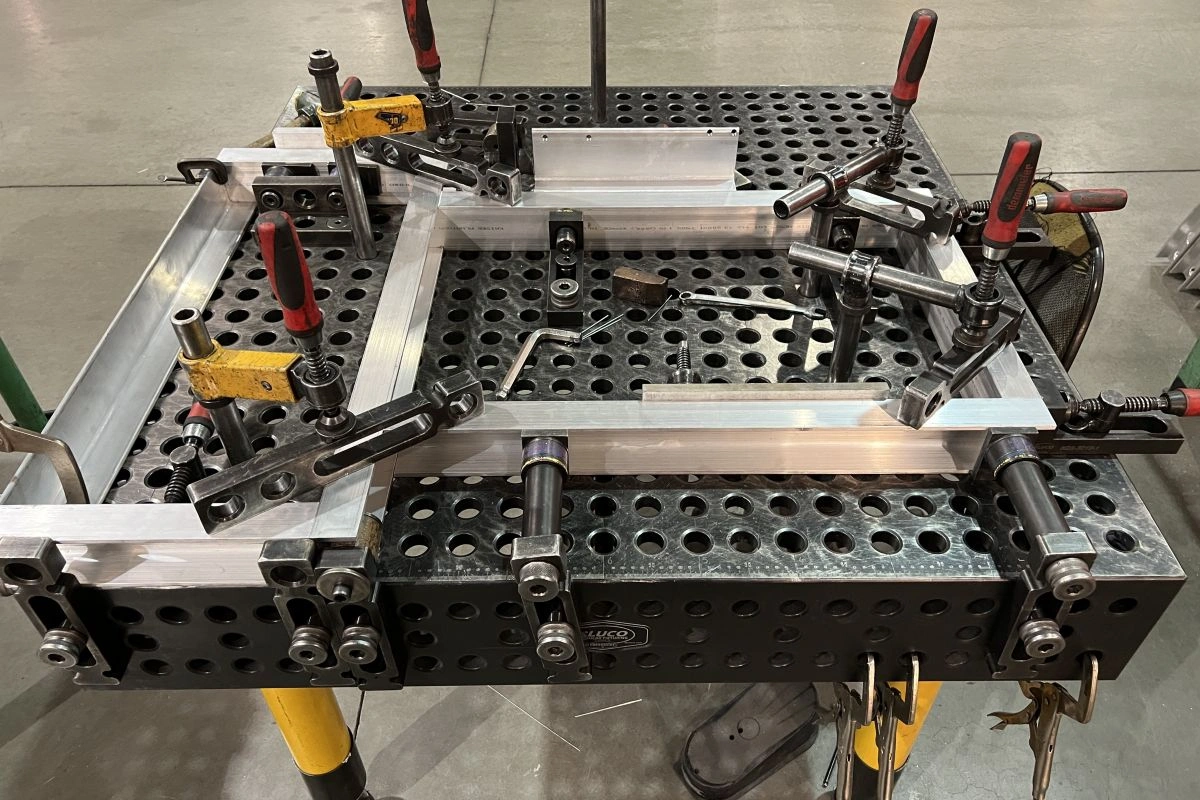

We use Demmeler 3D precision welding tables and clamping systems. This system makes it quick and easy to fixture parts for low-volume/high-mix fabrication and production. The table's 5-sided construction provides a high degree of dimensional accuracy. Parts are held precisely for tacking and welding, enabling us to maintain tight tolerances even on large weldments.

Welding Processes

Our welding processes include:

- GMAW: Gas Metal Arc Welding (MIG)

- GTAW: Gas Tungsten Arc Welding (TIG or Heli-Arc)

- RSW: Resistance Spot Welding

- SMAW: Shielded Metal Arc Welding (Arc)

Welding Certifications

Our welders are certified in AWS D1.1 and AWS D1.2 welding standards, giving confidence to our customers when they need quality structural welding work on steel and aluminum.

- D1.1: Certified Structural Steel Welding

- D1.2: Certified Structural Aluminum Welding

Welding & Fabrication Materials Used

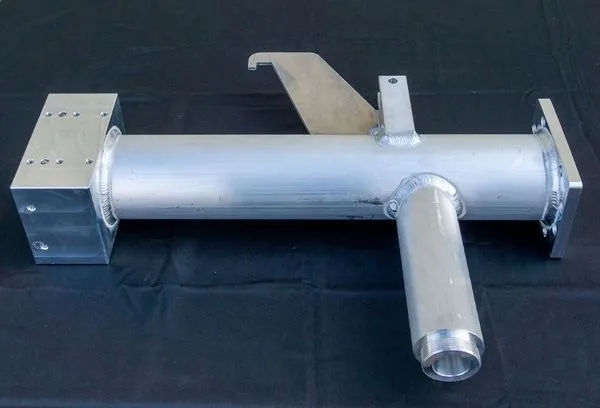

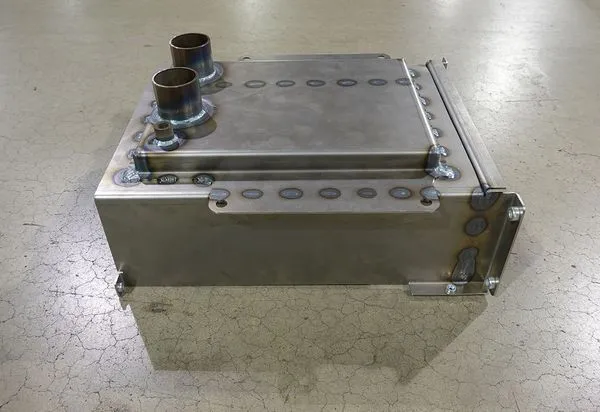

Our welding department has extensive experience with a wide variety of materials.

- Carbon & Low-Alloy Steels: Hot Roll A36, A572, A656, A514, Cold Roll, Hot Roll P&O

- Stainless Steels: 304, 316

- Aluminum Alloys: 3003, 5052, 6061, 6063

Welding & Fabrication Applications Across Multiple Industries

Manufacturers, Machine shops, Fabricators, OEMs, and Contractors across a broad range of markets trust our welding and fabrication services for their fabrication and manufacturing requirements.

| Brackets | Hoppers | Fixtures |

| Frames | Platforms | Racks |

| Skids | Housings | Consoles |

| Containers | Pallets | Command Centers |

| Enclosures | Machine Bases | Tanks |

| Machine Storage | Work Benches | Structures |

Why Choose Andersen for Welding Solutions

Since 1966, Andersen Industries has provided fabrication, welding, and precision machining services to manufacturers, machine and equipment builders, and contractors in California, Arizona, and Nevada. Our large state-of-the-art facility is equipped with a wide range of fabrication equipment and seasoned craftsmen providing our customers with the assurance and dependability they can count on.

As a single source for engineering and manufacturing, we fabricate, weld, machine, powder coat, and assemble your parts from a single location. Our engineers and shop personnel work closely during every step of the process to ensure each part or weldment is monitored and inspected to meet your specifications and requirements. Working with a full-service fabricator also means faster turnaround and delivery.